rockwell hardness test b and c|rockwell hardness comparison chart : advice A Rockwell hardness tester. The Rockwell scale is a hardness scale . 🔞 Garanta sua vaga no maior chat proibido do telegram, nele já temos mais de 35K de vídeos e mais de 756 membros ativos trocando conteúdo ️ 🌟Dentro dele vc vai achar INCESTO, TEENPORN, NOVINHAS e RAPE PLAY E MUITO MAIS 🔥 ⚠️ Entre já e ganhe 5tb de links proibidos Vai já🔻 CLIQUE AQUI 🔻

{plog:ftitle_list}

20 de jan. de 2024 · Sport Recife is going head to head with Santa Cruz starting on 20 Jan 2024 at 19:30 UTC . The match is a part of the Pernambucano, Serie A1. Currently, .

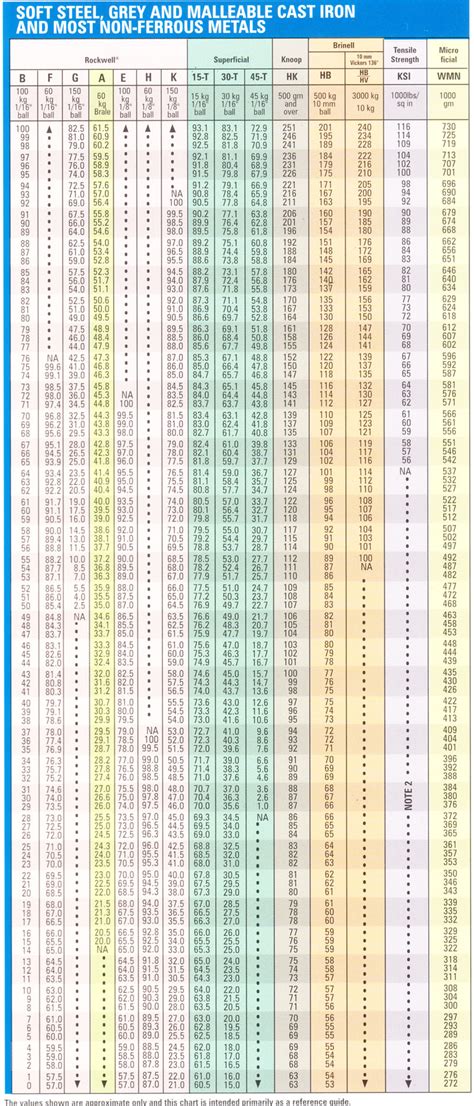

Most designers try to convert their hardness testing scales to more suitable ones like Rockwell hardness B and C scales. This article compares two types of Rockwell hardness to help you find the most ideal of the two for your hardness testing and conversion needs. A Rockwell hardness tester. The Rockwell scale is a hardness scale .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

A Rockwell C scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the diameter of the indentation only 0.019 inch, which is barely visible. The .

Home / How To Guide. Reading time: 1 minute. Hardness of a material is defined as its resistance to indentation. Rockwell hardness test measures the . The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell .

Rockwell Hardness Testing Reference Guide Newage Hardness Testers Selection Guide Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which .

The Rockwell hardness test is used for macro hardness tests, which are generally defined as tests that use indentation loads below or equal to 1 kgf. Therefore, a ground surface is usually sufficient, and sometimes no .Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). . Rockwell B and Rockwell C are . The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell B Scale. Used to test: aluminum, brass, and softer steels. Rockwell C Scale. Used to test: harder steels.

Rockwell hardness testing can determine the hardness of most metals, alloys and plastics. . The majority of applications are covered by the Rockwell C and B scales for testing steel, brass and other metals. However, the increasing use of materials other than steel and brass, as well as thin materials, necessitates a basic knowledge of the .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .Brinell Hardness HB: Rockwell C - HRC: Rockwell B - HRB: Vickers - HV : Enter a figure into any of the fields and click calculate, the nearest values in each scale is shown, or zero if out of range. Values are approximate and for guidance only. Reference Table: Steel hardness conversion chart - all values approximate.

Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool forIn the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is applied to the indenter on the test piece. . The resulting value is then translated to the Rockwell C scale of . Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method.

In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine.Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell scale being used (e.g., 60 kgf for the Rockwell A scale, 150 kgf for the Rockwell C scale). The load is applied for a .

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics.A variety of hardness-testing methods are available, including the Vickers, Brinell, Rockwell, . Rockwell A,B,C) Struers hardness conversion table (Vickers, Brinell, Rockwell B,C,D) This page was last edited on 18 December 2023, at 21:15 .1 Scope This part of ISO 6508 specifies a method of verification of testing machines for determining Rockwell hardness (scales A, B, C, D, E, F, G, H, K, N, T) in .

The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter . Fig. 3-17 Schematic Diagram of the Principle and Test Process of Rockwell Hardness Test (a) Add preload (b) Add main load (c) Unload main load. Hardness symbol: Head used: Total test force N: Scope of application: Applied range: HRA: Diamond cone: 588.4: 20-88:Description:-Hardness may be defined as resistance of metal to plastic deformation usually by indentation.However the term may also refer to stiffness or temper or resistance to scratch, abrasion or cutting. There are three general types of hardness measurements depending upon the manner in which the test is conducted.

The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.How To Operate The Analog Rockwell Hardness Tester ; Cylindrical Correction Chart; Hardness Conversion Chart - Rockwell "B" Hardness Range; Hardness Conversion Chart - Rockwell "C" Hardness Range; Hardness vs Minimum Thickness Chart; Rockwell Scale-Indenter-Load Chart; Contact Us. About Us; Store Policies; Blog ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .

Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).The Vickers hardness test is a macro and microhardness testing method, while the Rockwell test is used only as a macro testing method. The Rockwell test is a quick and direct process, while the Vickers hardness test is a slow process and requires other optical devices such as a microscope to measure the hardness of the object.

Brinell [HB] is one of the most common units used for listing the hardness of steel materials. The test is done with a 10 mm steel ball pressed with 3000 Kgf (6,614 Lbf). Common values for machined materials range from 100 HB for very soft materials up to 650 HB for heat-treated steels.. The advantage of Brinell [HB] over Rockwell [HRC/HRB], is that the whole range is .Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file. A scale indicating the hardness of materials, first used in 1919, when it was invented by Stanley P. Rockwell.The measurement has no units. The symbol is HR followed by a letter indicating one of a number of possible scales, described in the table below.

rockwell to brinell chart

rockwell testing chart

rockwell scale chart

O que é o VITRINE? É uma comunidade que se propôs incentivar o compartilhamento de projetos, trabalhos e novas ideias. Com tempo, o grupo tornou-se num crescente canal .

rockwell hardness test b and c|rockwell hardness comparison chart